Bagging & Filling

Through the recent partnership with VOTECH, FISCHBEIN enhances its ability to offer fully automatic Dosing, Bagging and Palletizing lines, as well as Pallet Wrapping and Stretch-Hooders. The Votech brand is known for providing high-precision and hygienic solutions in the food and powder sectors such as Milk powder, Pet Food, Animal Feeds, Food Flavours, Flour Milling, Fertilizers, Wood pellets, Horticulture, and associated products.

Bagging and filling machine – VBA

Description

The Tubular Form Fill and Seal machine is suitable for processing tubular foil into 5 to 50 Kg bags and can reach up to 1400 bags/hour. There are two possibilities for dosing, by volume or on weight. This bagging and filling machine can be designed for free-flowing products or poorly flowing products.

- Bag type: Tubular foil

- Volume/ weight: 5 – 50 Kg

- Up to 1400 bags/hour

Advantage(s)

- Accuracy

- User-friendly touchscreen display

- Low cost maintenance

- Robust

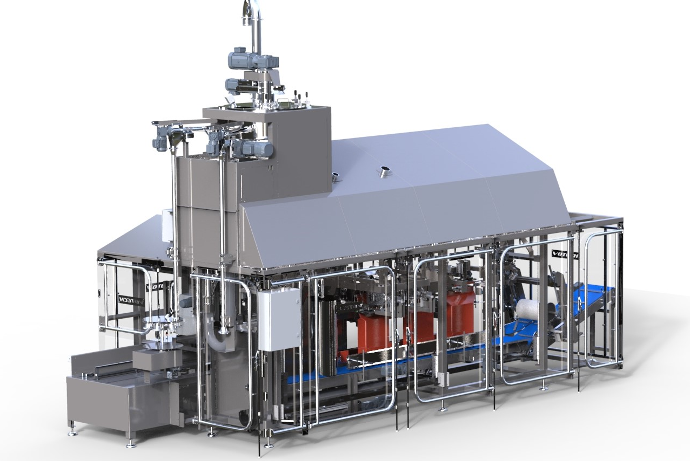

Bagging and filling machine – VLA

Description

The VLA bag filling machine can fill open mouth bags up to 1200 bags/hour. The empty bag is picked up from the bag magazine and presented to the spout by two arms. This bagging and filling machine is designed to place the bags one behind the other, allowing a very small footprint.

The bag is held continuously during transport and this results in a perfectly straight seal.

- Up to 1200 bags/hour

- Bag type: Open mouth bags

- Volume/ weight: 5 – 50 Kg

- Bag material: PE (with or without gusset), Paper (with PE inner liner), Polypropylene (laminated)

Advantage(s)

- The bag is held continuously during transport. This results in a perfectly straight seal.

- Easy adjustable for different bag sizes

- Robustly build

- Low maintenance

Bagging and filling machine – VLR

Description

The VLR bag filling machine can fill open mouth bags up to 1000 bags/hour. This bagging and filling machine is particularly suitable for a wide variety of open mouth bags and can be equipped with various closing methods. This machine can be equipped with gross or net weathers depending on the product and the output requested.

- Bag type: Open mouth bags

- Volume/ weight: 5 – 50 Kg

- Bag material: PE (with or without gusset), Paper (with PE inner liner), Polypropylene (laminated)

Advantage(s)

- The bagging and filling machine can be equipped with various closing methods.

- Easy adjustable for different bag sizes

- Robustly build

- Low maintenance

Bagging and filling machine – VLRB

Description

The VLR-B bag filling machine is specially designed to meet the high hygienic requirements of products such as milk powders, baby food, …

The dosing is very accurate by using a vertical screw feeder. The spout is designed to minimize dust generation during the dosing.

- Bag type: Open mouth bags

- Weight: 5 – 30 Kg

- Up to 400 bags/hour

Advantage(s)

- High Accuracy

- High hygienic environment such as milk powder, baby food, …

- Stainless steel

- Small footprint

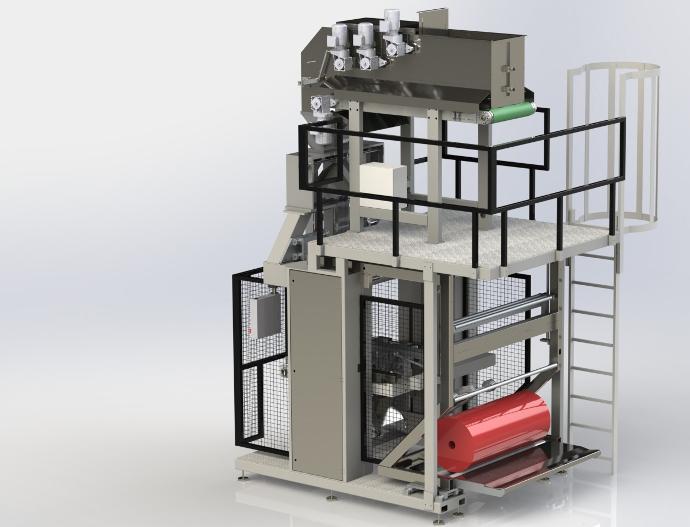

Vertical Form Fill Seal (VFFS)

Description

The VFFS form, fill and seal a bag from flat film.

This bagging and filling machine could be equipped with weighing or volumetric feeding system; to fill bags from 5 to 50kg or 10 to 130 litres.

The bags are filled in a vertical way which allows an output up to 1800 bags/hour.

- Volume/weight: 10 – 130 liters / 5 – 50 Kg

- Up to 1800 bags/hour

- Control: Touchscreen Display

Advantage(s)

- Continuous foil moving

- Robustly build and easy to operate

- Foil roll is easy to switch

- Low maintenance

Need this product ? Ask for a quotation